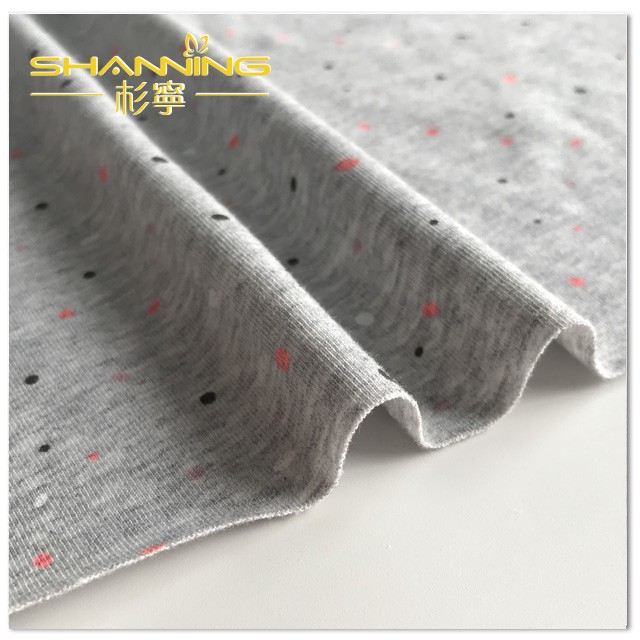

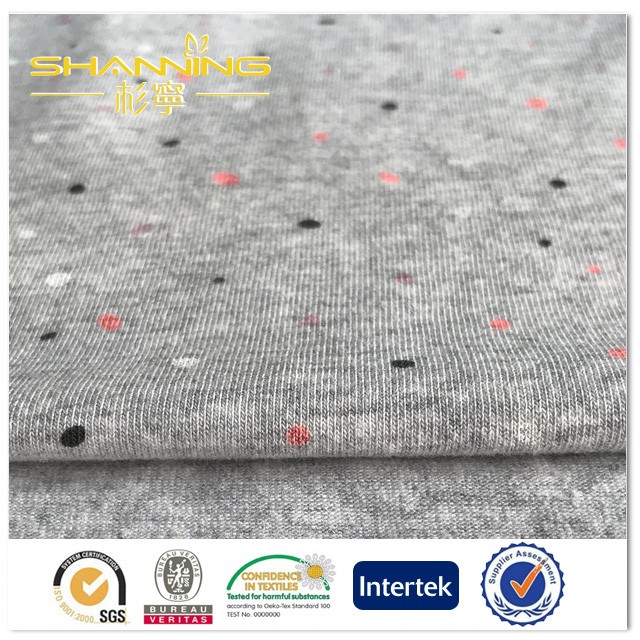

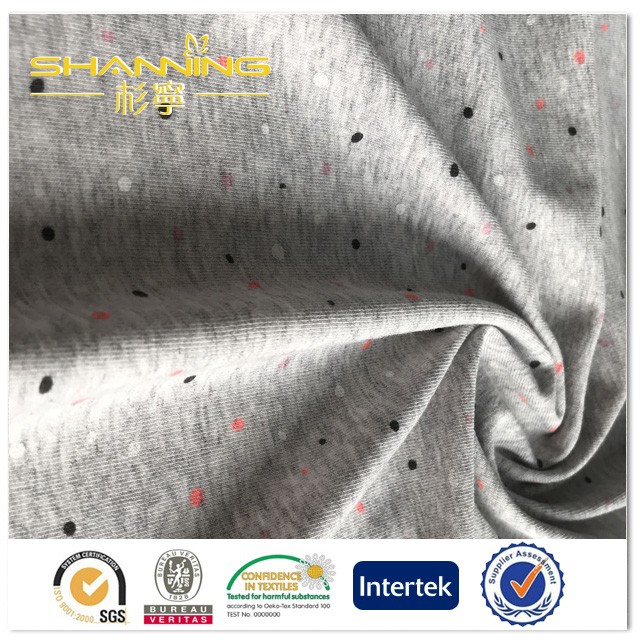

Online 65% Polyester 35% Cotton Rotary Printed Jersey Knit Fabric Textile Design

- SHANNING

- CHINA

- WITHIN 30 DAYS

- 40,000 KGS/MONTH

Polyester cotton printed Jersey Knit Fabric is normally treated by pigment print on solid or melange fabrics. Rotary print and plate print are both workable on this printed jersey knit fabric.

One of the main advantages of the cotton polyester blend is that it is more wrinkle-free. Because of poly cotton's wrinkle-free characteristics, it doesn't really need to be ironed. So it is a very good option for garments.

Advantage:

1. Like cotton feeling.

2. Good dimensional duration.

3. Good color fastness after washing.

4. T/C 65/36, T/C 70/30, T/C 80/20, T/C 90/10 or any other customized compositions are acceptable.

Product highlights:

1. Print method: Fluorescent printing can offer an obvious looking in a UV or poor light.

2. Customized designs, soft hand feeling, and any other after-treatments.

3. Only print or dyed & print are both workable.

Online 65% Polyester 35% Cotton Rotary Printed Jersey Knit Fabric Textile Design

| Product Type: | Print Jersey |

| Technica: | Weft Knitted |

| Item No.: | SJ-TC1801PT |

| Item Name: | Polyester Cotton Rayon Pigment Print Jersey Fabric |

| Composition: | 65% polyester 35% cotton |

| Yarn Count: | 21s T/C |

| Dyeing Technique: | Pigment print |

| Cuttable width: | From 58'' to 68'' |

| Tubular: | Open width |

| Weight: | 150/160gsm |

| Function(Optional): | Wicking, anti-pilling, moisture absorption, etc. |

| Feature: | Rotary print, 100% eco-friendly |

The advantages and disadvantages of different print facilities

We can provide different print methods according to the base fabric materials. Reactive print, disperse print, pigment print, transfer print and digital print, meanwhile rotary print and plate print are the most common way for print.

| Printing way | Advantage | Disadvantage |

| Rotary print | High output, continuous design, without joint marks, low cost | Small repeat, simple design. |

| Flat-screen print | big repeat, complex design, legible design and colour | Low output, presumable joint mark |

| Hand screen print | legible design and colour | small repeat, very low output, high costs. |

| Digital print | Unlimited design & repeat, any colourways, an excellent aspect | High costs |

OUR ADVANTAGE:

1) More than 12 years of experience in both fabric manufacture and trading.

2) We are cooperating with dyeing and printing mills who have qualified by Oeko-tex100 and Detox.

3) We have established a perfect supply chain after the past few years of exporting business.

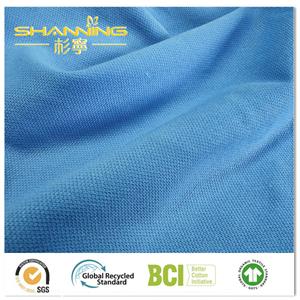

Fabric structure:

Single jersey knits, Interlock knits, Terry knits, Fleece knits, Rib, Pique, Ponta de Roma, sweater knits, Jacquard Knits, etc.

Processing Mode:

Solid dyed, yarn-dyed, print.

Yarn material:

Polyester, cotton, viscose, rayon, modal, bamboo, Tencel, linen and any other blend yarn compositions.

A4 size cutting or hanger sample or those samples less than half a yard are all FREE of cost, but the courier charge will be on buyer's account. For those samples which are more than half yard, pls contact us for further information and then decide how to deliver to you. Labdips or Stripe off will be sent by express courier with freight prepaid....more